(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- inCAD Library Home

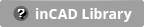

- > No.000129 Compact Workpiece Transfer

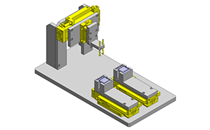

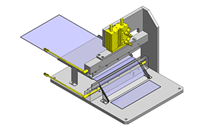

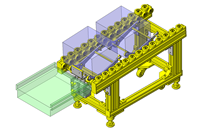

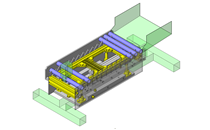

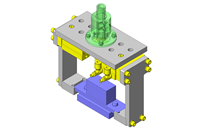

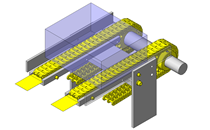

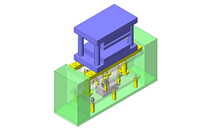

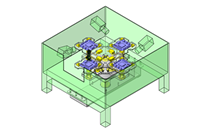

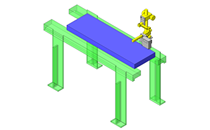

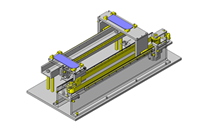

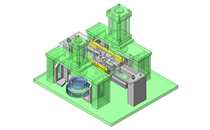

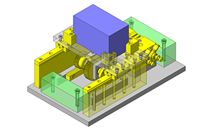

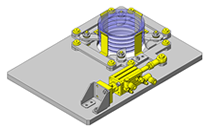

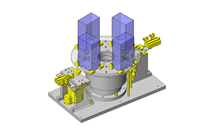

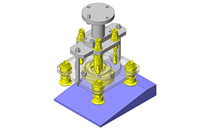

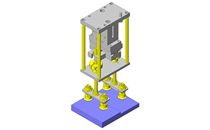

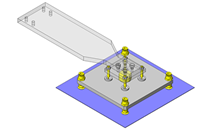

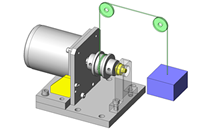

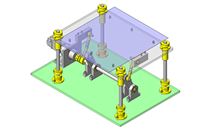

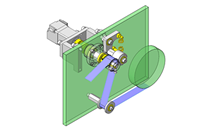

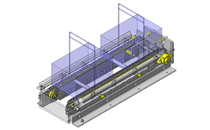

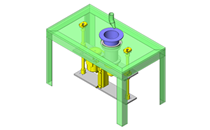

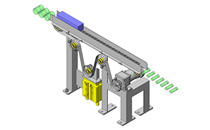

No.000129 Compact Workpiece Transfer

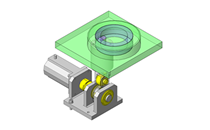

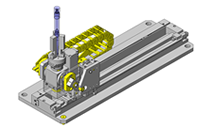

Extrusion Mechanism utilizing a linear guide

Relevant category

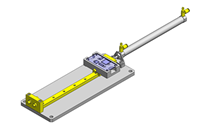

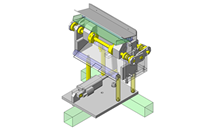

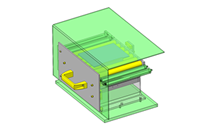

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

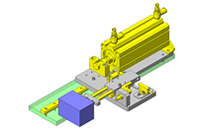

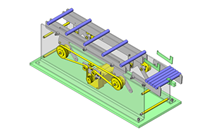

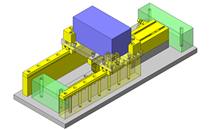

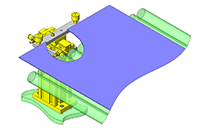

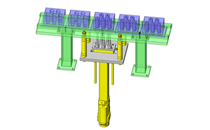

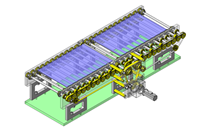

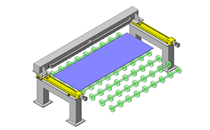

- A design where the linear guide is fixed and the rail moves to help avoid interference. A pusher attached to the end of the rail pushes the workpiece into the transfer box.

Points for use

- Useful in designs where air cannot be used to power the transfer mechanism.

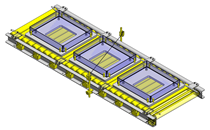

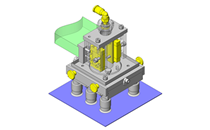

Target workpiece

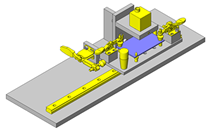

- Resin magazine (resin pallet)

- Outer dimensions: W67 x H70 x D80 mm

- Workpiece weight: 170 g x 3 pieces = 510 g

Design Specifications

Operating Conditions or Design Requirements

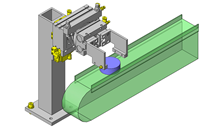

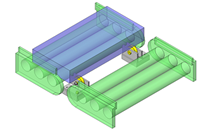

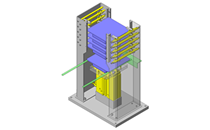

- Outer dimensions: W663 x H373 x D164 mm

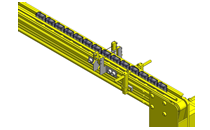

- Single axis robot stroke: 300 mm [movable stroke: 229 mm]

Required Performance

- Workpiece transfer positioning accuracy: ±0.1 mm

- Required workpiece transfer load capacity: 2.4 kg

- Workpiece transfer speed: 350 mm/s

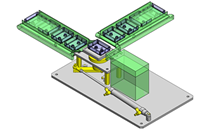

Selection Criteria for Main Components

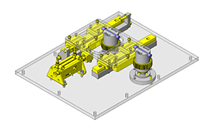

- Single axis robot

- A single axis robot that satisfies "maximum load capacity ≥ movable part mass + workpiece weight".

- A robot that satisfies the transfer speed specification and is reasonably priced.

- A robot that satisfies the transfer stroke.

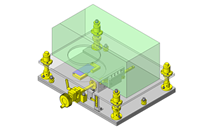

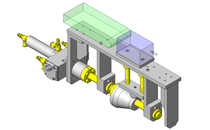

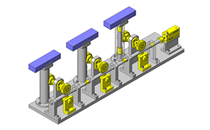

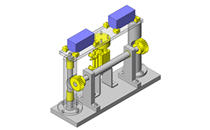

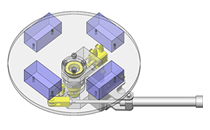

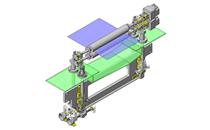

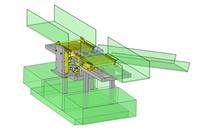

- Linear Guides

- Linear guides that satisfy the allowable moment.

Design Evaluation

Verification of main components

- Whether the linear guides withstand the loading moment and whether the robot is suitable for the transfer specifications (load capacity, speed, stroke) are verified.

- Linear guide allowable moment

- Linear guide allowable moment: MB = 104 N·m (yawing)

- Single axis robot maximum push force: f = 150 N

Distance from rotation center to acting point: I = 0.136 m

Safety factor: e = 5 times

Loading moment: M = 150 N x 0.136 = 20.4

Required allowable moment: MB > M x e = 20.4 x 5 = 102 N·m

Therefore, linear guides with allowable moment of 104 N·m are selected.

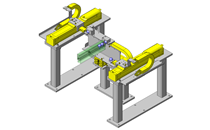

- Transfer mass: 2.25 kg

- Linear guide rail: 0.92 kg, slide plate: 0.58 kg, pan: 0.32 kg, claw holder: 0.37 kg, claw: 0.06 kg

- Workpiece mass: 0.17 kg x 3 pieces = 0.51 kg

- Friction coefficient: 0.3 (tentative value)

- Required operation power: workpiece mass x friction coefficient = 0.51 kg x 0.3 = 0.153 kg

- Required transferable mass

- 2.25 kg + 0.153 kg = 2.403 kg < 25 kg (single axis robot maximum load capacity)

- Required speed

- 1 cycle: 3 s

Required speed = (transfer distance x 2) ÷ 3 = 458 mm ÷ 3 s = 153 mm/s

As acceleration/deceleration time is not considered in this equation,

Acceleration: 0.1 G = 980 mm/s² (tentative value)

Setting speed: 350 mm/s < 500 mm/s (single axis robot maximum speed)

Acceleration time = speed ÷ acceleration = 350 mm/s ÷ 980 mm/s² = 0.33 s

Moving distance during acceleration/deceleration = acceleration x acceleration time ÷ 2 = 980 mm/s² x 0.33 s ÷ 2 = 53.4 mm

Moving distance at setting speed = distance per cycle - moving distance per cycle during acceleration/deceleration = 229 mm x 2 - 53.4 mm x 4 = 244.4 mm

Moving time at setting speed = moving distance at setting speed ÷ setting speed = 244.4 mm ÷ 350 mm/s = 0.77 s - 1 cycle = 0.77 s + 0.33 s x 4 = 2.09 s

- Marginal time: 3 s - 2.09 s = 0.91 s

- 1 cycle: 3 s

Other Design Consideration

- Since linear guide is mounted directly above the workpiece transfer table, a drip pan is installed to catch excess grease.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category