(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

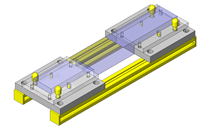

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- inCAD Library Home

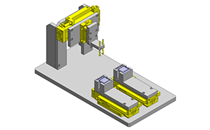

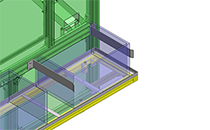

- > No.000052 Workpiece Confirmation Process

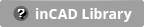

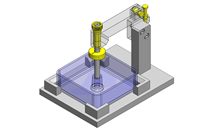

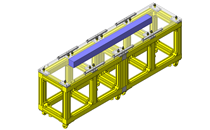

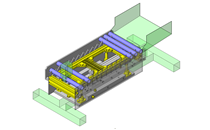

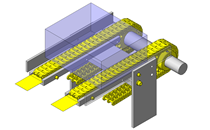

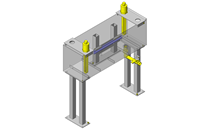

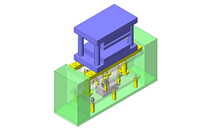

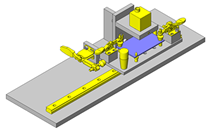

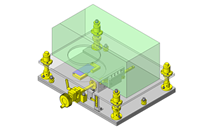

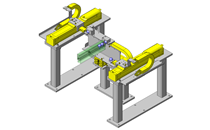

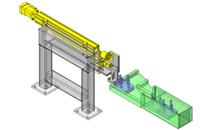

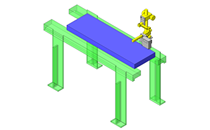

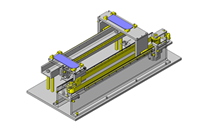

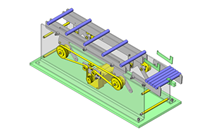

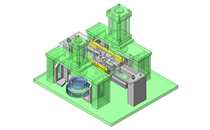

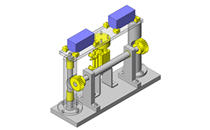

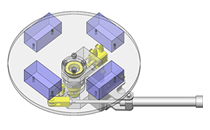

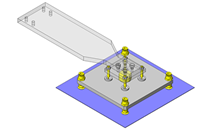

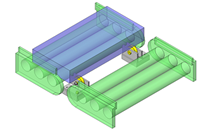

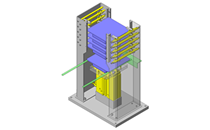

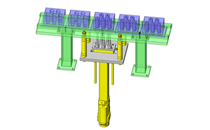

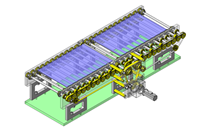

No.000052 Workpiece Confirmation Process

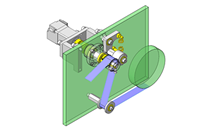

Workpiece confirmation process with photoelectric sensor.

Relevant category

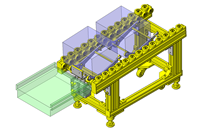

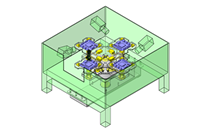

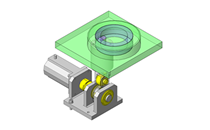

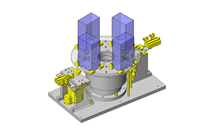

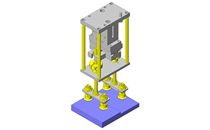

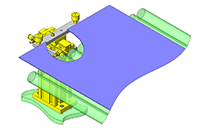

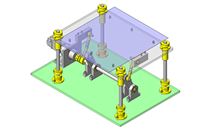

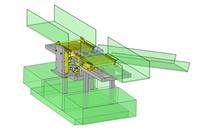

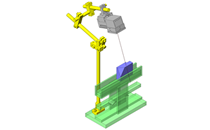

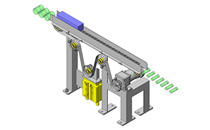

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

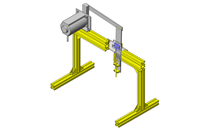

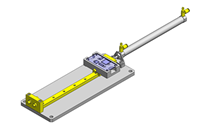

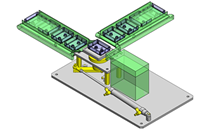

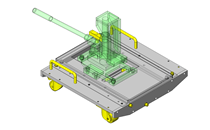

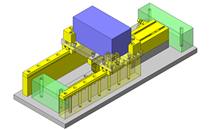

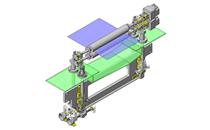

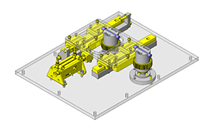

- Detects passing components or assemblies on a conveyor.

Target workpiece

- Sheet metal case.

- Pallet

- Workpiece size: 270 x 305 x 50

Design Specifications

Operating Conditions or Design Requirements

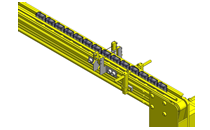

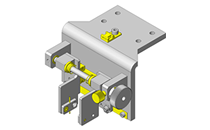

- Conveyor guide width: 345

- External dims.: W475 x D1350 x H159

Required Performance

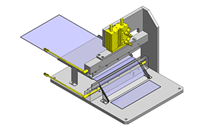

- Workpiece・Case weight: 8kg

Selection Criteria for Main Components

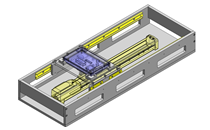

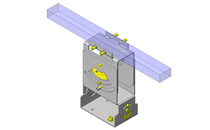

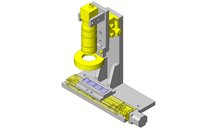

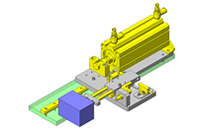

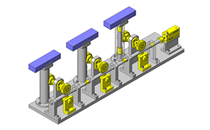

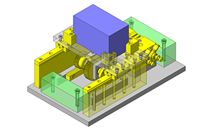

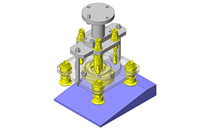

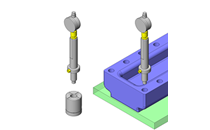

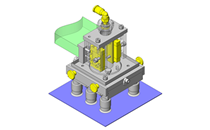

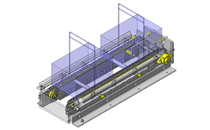

- Motor roller

- The integrated motor saves space by not requiring an external motor.

Design Evaluation

Verification of main components

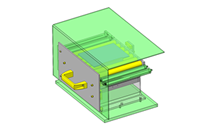

- Verify that the motorized roller can move the material on the conveyor.

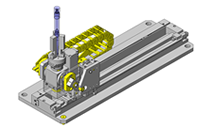

- Motor roller selection

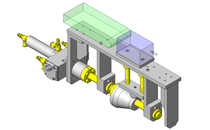

- ① Required tangential force (Roller transfer ability) confirmation

Conveyed object weight M = 8kg

When rolling friction coefficient μ = 0.04,

Required tangential force F[N] = 9.8 × M × μ = 9.8 × 8 × 0.04 = 3.14N - ② Temporary selection of model number

MOR38-400-10 - ③ Determining required number of rollers

When motor roller's starting tangential force FK = 37.3N,

Conveyance capacity FH[N] = FK × 0.9 = 37.3 × 0.9 = 33.57N

Required number of rollers

n = F / FH = 3.14 / 33.57 = 0.094pc. (* 1pc. is capable of conveyance)

● For safety reasons, be sure that load always rides on two rollers. - ④ Determining roller length

From Load: Length (L = 400) x Width (W = 320), roller length 400 (80mm margin) is selected.

- ① Required tangential force (Roller transfer ability) confirmation

Other Design Consideration

- One roller is adequate as shown in the calculations above, but considering that if there are any changes in the system with the load on the rollers, rollers come out of alignment, variation in the motor speed, and etc... minimum of two rollers need to engage each assembly tray component.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category

-

Relevant category

-

Relevant category