(!)Due to Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended environment.

Our Business Hours:

Mon. - Fri. 8 a.m. - 6 p.m.

Mon. - Fri. 8 a.m. - 6 p.m.

All Categories

Categories

- Automation Components

- Linear Motion

- Rotary Motion

- Connecting Parts

- Rotary Power Transmission

- Motors

- Conveyors & Material Handling

- Locating, Positioning, Jigs & Fixtures

- Inspection

- Sensors, Switches

- Pneumatics, Hydraulics

- Vacuum Components

- Hydraulic Equipment

- Spray Equipment And Accessories

- Pipe, Tubes, Hoses & Fittings

- Modules, Units

- Heaters, Temperature Control

- Aluminum Extrusions, Framing, Support & Posts

- Casters, Leveling Mounts, Posts

- Doors, Cabinet Hardware

- Springs, Shock Absorbers

- Adjustment/Fastening Components, Pins, Magnets

- Antivibration, Soundproofing Materials, Safety Products

- Fasteners

- Materials

- Wiring Components

- LAN Cables / Industrial Network Cables

- Equipment Specific Cables

- Cordsets

- Computer & AV Cables

- Wire/Cable

- Connector (General Purpose)

- Crimp Terminal Components

- Cable Organization

- Cable Gland Components

- Cable Bushing/Clip/Sticker

- Screw/Spacer

- Cable accessories

- Tube

- Electrical Conduits

- Duct/Wiring

- Electrical Wiring Tools

- Dedicated tools

- Soldering supplies

- Electrical & Controls

- Cutting Tools

- Carbide End Mill

- HSS End Mill

- Concrete Drill Bits

- Milling Cutter Insert / Holder

- Core Drill Bits

- Customized Straight Blade End Mill

- Dedicated Cutter

- Crinkey Cutters

- Turning Tool

- Drill

- Cutting Tool Accessories

- Screw Hole Related Tools

- Reamer

- Electric Drill Bits

- Chamfering, Centering Tool

- Hole Saws

- Magnetic Drill Press Cutters

- Step Drills

- Wood Drills & Cutters

- Processing Tools

- packing & logistics storage supplies

- Safety Products

- research and development & cleanroom supplies

- Press Die Components

- Plastic Mold Components

- Ejector Pins

- Sleeves, Center Pins

- Core Pins

- Sprue bushings, Gates, and other components

- Date Mark Inserts, Recycle Mark Inserts, Pins with Gas Vent

- Undercut, Plates

- Leader Components, Components for Ejector Space

- Mold Opening Controllers

- Cooling or Heating Components

- Accessories, Others

- Components of Large Mold, Die Casting

- Injection Molding Components

- Purging Agent

- Injection Molding Machine Products

- Accessories of Equipment

- Auxiliary Equipment

- Air Nippers

- Air Cylinders

- Air Chuck for Runner

- Chuck Board Components

- Frames

- Suction Components

- Parallel Air Chuck

- Special Air Chuck

- Mold Maintenance

- Heating Items

- Heat Insulation Sheets

- Couplers, Plugs, One-touch Joints

- Tubes, Hoses, Peripheral Components

Applications

Brands

- Webcode Seach | Series

-

#CODE

- Discontinued Products

- inCAD Library Home

- > No.000088 Adjustable Fixing Jig

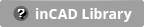

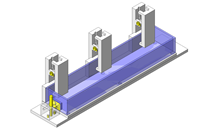

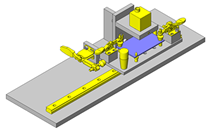

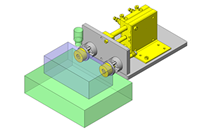

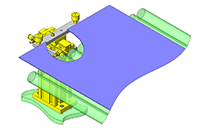

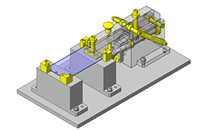

No.000088 Adjustable Fixing Jig

Clamping mechanism capable of angular adjustment

Relevant category

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- A jig that can adjust the clamping angle to accommodate different size workpieces.

Points for use

- Lateral and rotational adjustments can be made with the lever.

Target workpiece

- Resin box.

- Small workpiece outer dimensions: W100 x D50 x H100.

- Large workpiece outer dimensions: W100 x D200 x H100.

Design Specifications

Operating Conditions or Design Requirements

- Outer dimensions: W500 x D250 x H108.

Selection Criteria for Main Components

- Clamp lever.

- Selected to allow adjustments to be made to the jig.

- Toggle clamp.

- Horizontal type required for this design.

- Tension spring.

- When the floating portion is not clamping, the spring returns the floating part to its original position.

Design Evaluation

Verification of main components

- Verify that the tension spring has the required load.

- Spring load.

- Calculation formula: reaction force F = kx + initial tension.

- Initial tension: 0.88N.

- Assumed deflection when pulled:

x = 5.0mm (when set)

x = 8.3mm (when rotated by 45°) - If spring constant: k = 0.3N

mm is selected. - Assumed load:

F = (0.3 x 5 + 0.88) x 2 = 4.76N (when set)

F = (0.3 x 8.3 + 0.88) x 2 = 6.74N (when rotated by 45°)

(The load is obtained by multiplying by 2 because the load is applied at two positions: upper and lower.)

Explore Similar Application Examples

Page

-

/

-

-

Relevant category